Overview

Thanks

Thanks to its excellent grip on the product, PUMA can achieve parallel slices and high yields even with bone-in products. A glance inside the blade box reveals a thin blade designed for precise cutting.

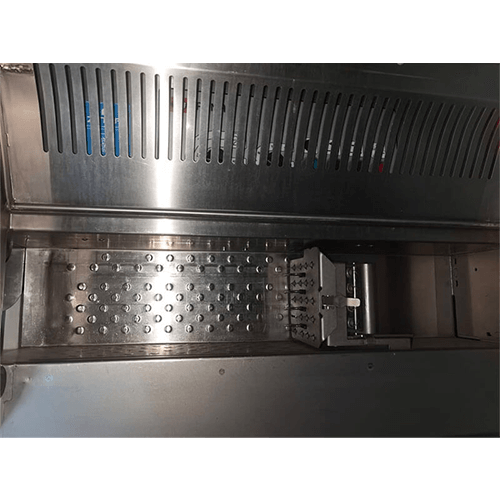

Dimple Plate: Creates a cushion of air between the studs, guiding the product smoothly to the blade while reducing friction.

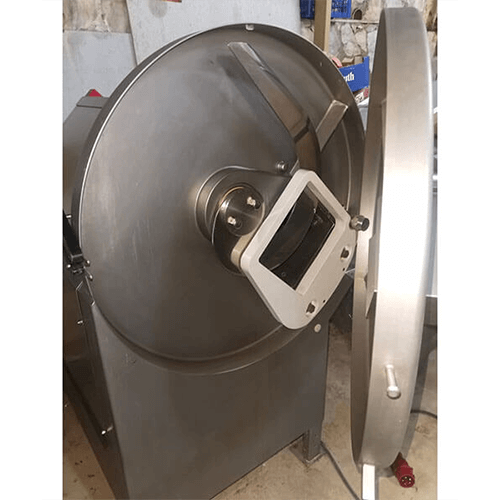

Touchscreen: Operating PUMA has never been easier. The new touchscreen interface allows for quicker and more comfortable operation. Data can be saved and software updates transferred using a USB stick.

Cleaning Position: The discharge belt, like other machine components, can be easily adjusted to an upright position for optimal cleaning, avoiding back strain. This is just one of many features that highlight PUMA’s ergonomic design.

PUMA boasts exceptional flexibility, handling various products like steak, schnitzel, ham, or cheese with ease. Its defining features are performance and precision, slicing products at temperatures as low as -4°C (24.8°F). Depending on the model, it can process products up to 700 or 1,100 mm in length. The PUMA E/EB model allows for cutting minute steaks and slices from a single product and integrates seamlessly into the production process through package formation.

Features:

- High performance and precision, even with bone-in products.

- Easy and fast operation via touchscreen; USB port for data backup and software updates.

- Optimal exploitation of the product through residual piece optimisation (E/EB).

- Enhanced efficiency with the precision sickle blade and intelligent product feed holder.

- Easy cleaning due to optimal hygienic design and ergonomics, such as the discharge belt’s easy adjustment to cleaning position without back strain.

- Automatic ejection of the remaining piece by the pneumatic product holder (optional).

- Portable with travel gear for easy and flexible movement (optional).

- HS (High-Speed) model available for increased capacity (optional).

Dynamic Feeding System (DFS):

Ensures precise cutting results and evenly thick slices as standard. It synchronizes slicing with continuous product feed, preventing wedge slices.

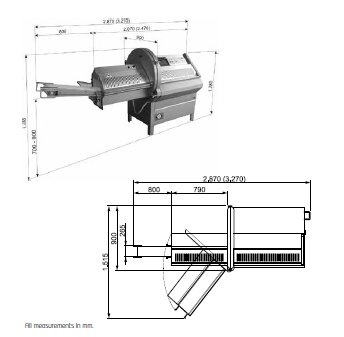

Technical Details:

- Max Cut-off Length (mm/inch): 0.5-70; 1/50″ – 24/5″, 0.5-250; 1/50″-94/5″

- Cuts/Minute (Double Blade): 400

- Cross Section of Product (mm/inch): 220 x 240; 8 3/5″ x 9 1/2″

- Max. Infeed Length (mm/inch): 700; 27 3/5″

- Dimensions without Belt (L/W/H mm): 2110/900/1480

- Dimensions with Belt (L/W/H mm): 2750/900/1480

- Connecting Load (kW): 3.4/3.5

- Weight with/without Belt (kg/lb): 305/672.5; 285/629